- Have any questions?

- +91 7897 474 376

- info@shobaprad.com

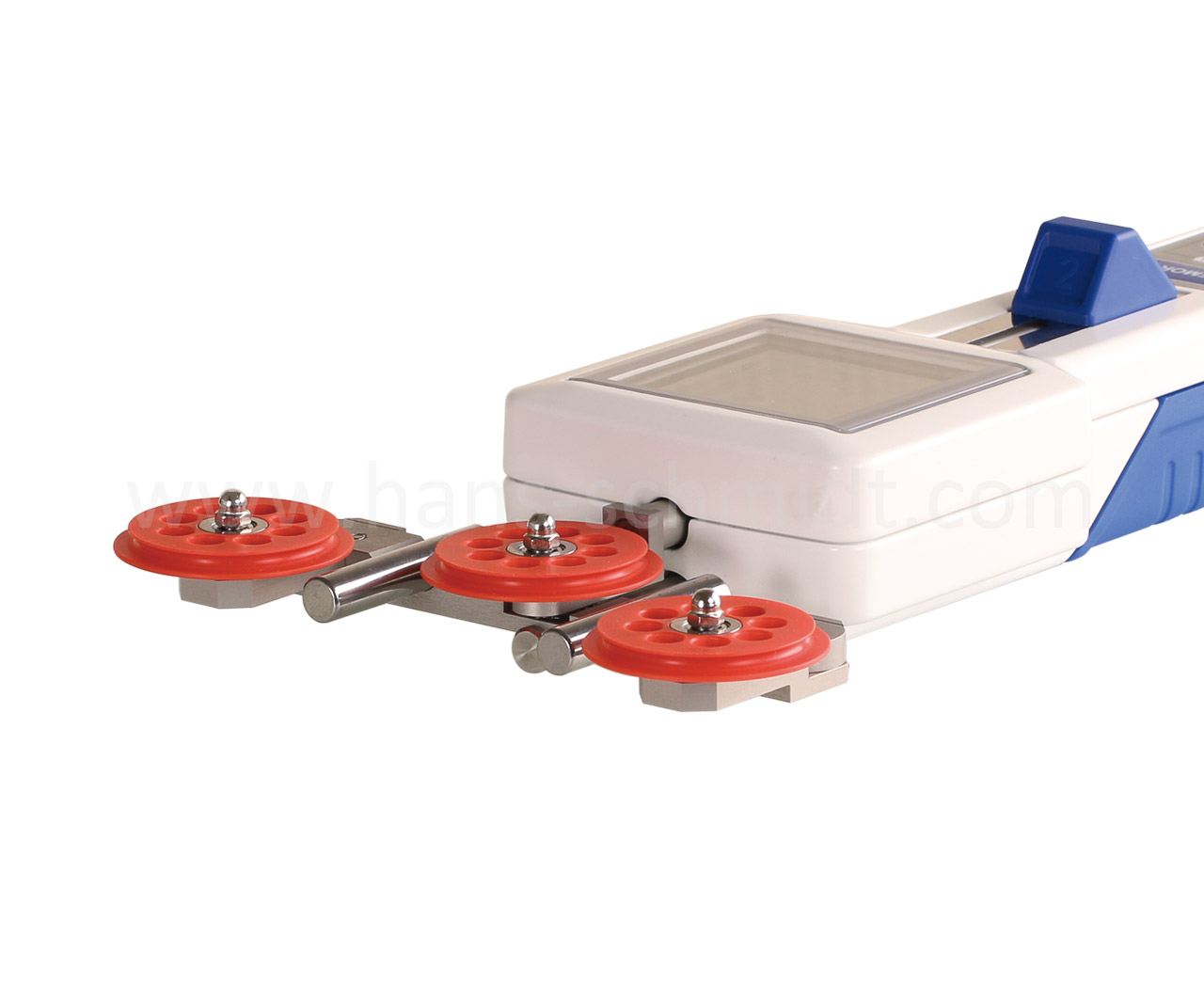

Tension Meter DTXF

December 12, 2019

Tension Meter DTXE

December 12, 2019Tension Meter DTSF

4 Tension ranges available

from 1 – 200 cN up to 20 – 2000 cN

Applications for fragile filaments with Ø up to max. 1.5 mm

Electronic tension meter for different industries

Tension meter with many functions as turnable display, and possibility of custom made calibrations

Special Features

• Large, v-grooved guide rollers with 32 groove diameter, ball bearing mounted

• Large bending radius assures gentle handling of the material being measured

• Special guides on the bracket assembly permit easy material acquisition

• Calibration with Polyamide Monofilament (PA)

• Tension meter DTSF with large, backlight LCD-display

• 3 different display modes:

– numeric

– numeric with bargraph

– numeric with graph (Time-Tension)

• The display rotates in 90° steps for better reading

• New, unique, force reduced material catching system

• Automatic „Zero-Setting“ in each measuring position using a special sensor technique

• 4 Material memory locations for customer made calibrations

• Calibration adjustment for fine tuning of the calibration if material differs from the used calibration material

• Programmable MIN- and MAX alarms: indication in the display, if reading is out of limits

• High speed data sampling (internal 8 kHz) and recording of MIN-, MAX-, last reading, PEAKS, average and standard deviation

• Selectable units of measurement: cN, daN, g, kg, N, lb

• Menu set-up in English or German language

• Flexible menu set-up to meet operators demand

• Some functions can be password protected

Note : Tension meter DTXF offers additional features, like interface, statistical evaluation on PC and a large internal memory.

Standard Features

• Everything in operator’s view:

– the guide rollers

– the measured material

– the readings

• Filament guide and roller shifting mechanism ensure easy acquisition of the running material

• Rubberized handle provides a secure hold in the operators‘ hand

• Tension meter with rugged aluminium housing

• LiPo accumulator (approx. 40 hours continuous operation) with AC adapter

• CE certified, interference resistant against static electrifications

• Certificate of Compliance with the order 2.1 according EN 10204 is included

• Optionally available: Inspection Certificate 3.1 according EN 10204 with calibration report

Available Models

| Model | Measuring Range |

Resolution | Measuring Head Width* |

SCHMIDT Calibration Material PA** |

| DTSF-200 | 1 – 200.0 cN | 0.1 cN | 140 mm | 0.12 mm Ø |

| DTSF-500 | 1 – 500.0 cN | 0.1 cN | 140 mm | 0.20 mm Ø |

| DTSF-1000 | 10 – 1000 cN | 1 cN | 140 mm | 0.30 mm Ø |

| DTSF-2000 | 20 – 1000 cN | 1 cN | 140 mm | 0.50 mm Ø |

* Outer distance between outside guide rollers

** Suitable for 95 % of applications